General Bottle

Morphology

HOME:

Bottle Glossary:

Bottle Morphology

To properly describe the physical attributes of historic bottles some standardization of descriptive terms is necessary. The terminology noted on the illustration below is that which is commonly used to describe the different physical attributes - or morphology - of a typical bottle and what is used on this website. (For a higher quality version of the illustration click on it.)

The definitions of these terms are included here as well as on the Glossary page for convenience. It is generally much easier to visualize different bottle parts with a drawing than to picture them in ones head from just a definition. This morphology page is frequently hyperlinked back to throughout this website to explain the terminology being used. Generally, the first definition or description noted for each term is that which is generally used on this website. Additional variations or usage of these terms use are also noted as appropriate.

As noted, there exists a lot of variation in the terminology used by various authors to describe the physical features of bottles. The information found here is a composite from many different sources but is not identical to any particular one. The references include (but not limited to): Howard (1950), Tooley (1953), Switzer (1974), White (1978), Berge (1980),Wilson (1981), Jones (1986), Fike (1987), King (1987), Creswick (1987), Jones & Sullivan (1989), and Fike (1998).

Close this "pop-up" page when finished by clicking the "X" in the upper right corner.

Base - The bottom of the bottle; the surface upon which the bottle stands. Any measurements of the base on this website are of the greatest diameter (round) or greatest width and depth (non-round). The "resting point" of the bottle is usually the extreme outside edge of the base. See the Bottle Bases page for much more information on bottle bases.

Body - The main content containing portion of the bottle, which lies between the shoulder and heel (insweep). See the Bottle Body & Mold Seams page for much more information on bottle bodies.

Bore (Orifice, Throat) - The opening in the top of the finish from which the bottle contents are accessed. Also called the aperture, corkage, orifice, opening, throat, or mouth of the bottle. See the Bottle Finishes page for much more information on finishes and finish parts.

Collar - Used often to denote the lower part of a two part finish, i.e., the finish portion which lies immediately below the lip or upper finish part (see finish below). Some use the term collar to refer to the upper portion of a two (or more) part finish or even to the entire finish if it is composed of only one part (U. S. Patent Office 1875). The terms "string rim", "lower part", "skirt" or ring are also used to refer to what is called a collar here. See the Bottle Finishes page for more information on finishes and finish parts. Also see ring below. This is one of several variably and confusingly used terms regarding finishes.

Embossing - Raised lettering, designs, or graphics on the surface of the bottle that are formed by incising or engraving on the inside mold surface(s). Also see plate below and the Bottle Body & Mold Seams page for more information on bottle bodies and embossing.

Finish - Simply put, the finish is typically everything above the distinctive upper terminus of the neck. It refers to the combination of the lip (upper part) and collar (lower part) of a finish, if both are present, or any other distinct parts if present. The term finish originates as a glassmakers reference to the final process of making a mouth-blown bottle - completion or "finishing" of the lip and upper portion of the neck. Generically, a finish can have one-part, two-parts (like in the illustration above), or three-parts; finishes rarely have more than three parts (Jones & Sullivan 1989). The entire finish on a bottle is also referred to sometimes as a "top," "lip" or "mouth" (White 1978), See the Bottle Finishes page for much more information on finishes.

Heel (Insweep) - The lowest portion of the bottle where the body begins to curve into the base. The heel usually terminates at the resting point of the bottle, i.e., the extreme outer edge of the base. Put another way, the heel is the transition zone between the horizontal plane of the base and the vertical plane of the body. Also called the "basal edge" (Firebaugh 1983).

Insweep - See Heel.

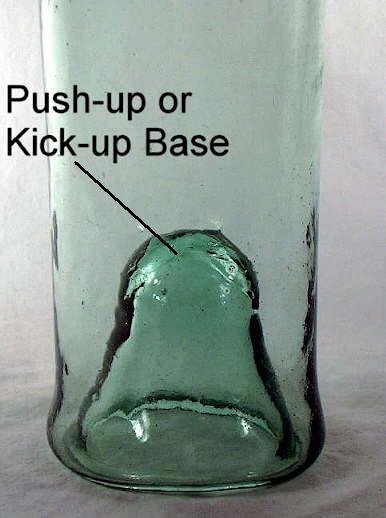

Kick-up (Push-up) - See push-up below which is synonymous with kick-up. This is not shown in the illustration above, but is pictured below. See the Bottle Bases page for more information.

|

Side mold seam on the neck of a 1905-1915 era beer bottle with a tooled finish. |

Lip - This is one of the more confusing and variably used terms used in reference to bottle morphology. Even on this site, lip has two meanings depending on the context, though both uses are better described with other terms. It is used to describe the extreme upper surface of the finish, though the term rim is preferred (both are often used together on this website). Lip is also used by some - and occasionally on this website as indicated by the illustration above - to refer to the upper part of a multiple part finish (Jones & Sullivan 1989). The term is also frequently used as a shorthand reference for the entire finish - lip and collar together. For added confusion, the term collar is used by some to refer to what is called a lip here - the upper part of the finish or the entire finish if it is composed of only one part. See the Bottle Finishes page for much more information on finishes and finish parts.

Mold Seam(s) - Raised lines on the body, shoulder, neck, finish, and/or base of the bottle that are formed where the edges of different mold sections parts came together. (Picture to the right.) Also called "mold line(s)" (White 1978) and in the glass industry - "joint-marks" or "parting lines" (Scholes 1952; Tooley 1953). See the Bottle Body & Mold Seams page for more information on bottle bodies and mold seams.

Neck - The (usually) constricted part of a bottle that lies above the shoulder and below the finish. Some authors have considered the upper neck as part of the finish also since the upper neck was very often manipulated as part of the finishing process with mouth-blown bottles (Ketchum 1975, White 1978). However, on this web site the finish is considered to begin where the conformation of the upper neck abruptly changes or alters (typically increases in diameter) at the base of the finish.

Orifice - See Bore.

Plate - Used to describe an interchangeable, typically iron, engraved plate which was

used in a bottle mold to produce different embossing patterns for the same type

bottle. By simply taking out one engraved plate and replacing it

with another differently engraved plate, the same mold could produce scores of unique and

individually embossed bottles of the same shape and design. Commonly called a "slug plate" by

collectors, though more properly called simply a plate and bottles from this type

mold referred to as having been produced in a "plate mold" (Jones & Sullivan 1989).

Plate - Used to describe an interchangeable, typically iron, engraved plate which was

used in a bottle mold to produce different embossing patterns for the same type

bottle. By simply taking out one engraved plate and replacing it

with another differently engraved plate, the same mold could produce scores of unique and

individually embossed bottles of the same shape and design. Commonly called a "slug plate" by

collectors, though more properly called simply a plate and bottles from this type

mold referred to as having been produced in a "plate mold" (Jones & Sullivan 1989).

The body morphology illustration above shows embossing within the plate section of the bottle mold. It also shows the impressions made by the screws that held this early plate in place in the mold (the bottle style shown is from the 1850-1870 era and the screw marks are occasionally visible on finished bottles). Plate molds made all kinds of proprietary bottles (i.e., bottles with embossing unique to a specific customer) affordable since an expensive, unique, entire mold often costing several hundred dollars did not have to be made for each customer. Instead a simple engraved plate costing a few dollars was all that was needed to personalize a mold (Whitall, Tatum & Co. 1880a). The picture to the left above is of an original cast iron mold plate dating from between 1915 and 1918. It was used for producing prescription bottles for a Detroit (MI.) pharmacy which was listed in the Detroit business directories only during that time period (Mark Hawkins pers. comm. 2006). The engraving on the plate was reversed of course so that the embossing will read correctly on the finished bottle. See the Bottle Body & Mold Seams page for more information.

Push-up

(Kick-up) - This feature is not shown in illustration above but is pictured to the

right on a mid-19th century

free-blown French wine (Muscat) bottle. A push-up is a steep rise or pushed-up portion of the base which

somewhat reduces the interior volume of the bottle, though it was done primarily for

strength enhancing, stability, and/or possibly to collect content sediment (Jones 1971a).

The term kick-up is synonymous with push-up and both terms may be used

interchangeably on this website. Some glassmakers also called this feature

a "shove-up" (Illinois Glass Co. 1906). See the

Bottle Bases page for more information.

Push-up

(Kick-up) - This feature is not shown in illustration above but is pictured to the

right on a mid-19th century

free-blown French wine (Muscat) bottle. A push-up is a steep rise or pushed-up portion of the base which

somewhat reduces the interior volume of the bottle, though it was done primarily for

strength enhancing, stability, and/or possibly to collect content sediment (Jones 1971a).

The term kick-up is synonymous with push-up and both terms may be used

interchangeably on this website. Some glassmakers also called this feature

a "shove-up" (Illinois Glass Co. 1906). See the

Bottle Bases page for more information.

Rim

- The extreme upper surface of the finish where the bore (throat) begins.

Simply put, it was the

topmost portion of a bottle or jar; see the image to the left. Also

called the lip by some.

Rim

- The extreme upper surface of the finish where the bore (throat) begins.

Simply put, it was the

topmost portion of a bottle or jar; see the image to the left. Also

called the lip by some.

Ring - Alternative name for the lower part (or collar) of a two or more part finish if it is narrow and rounded on the outside (resembling a glass "wedding band" or ring at the base of the finish). See collar above.

Sealing surface (Not specifically noted in the illustration above) - At its simplest, this is the surface where the closure and finish mesh to seal the contents inside. The extreme top portion of the finish (rim) is sometimes referred to as the sealing surface though that is dependent on the type finish as to whether it actually accomplished this task. For example, the sealing surface on a cork finish bottle is primarily the inside of the bore or throat. The term is most applicable to external threaded finish/closure combinations for which the rim is the sealing surface on which the screw cap twists down to and seals against (like the modern jar pictured to the left above). One major exception to that arrangement was/is the Mason patent fruit jar on which the sealing surface was actually the edge of the shoulder just below the threads - not the rim. This is known as the "Mason shoulder seal" (Creswick 1987). Click here for Mason screw thread picture.

Seam - See Mold Seam.

Shoulder - The portion of the bottle which lies between the point of change in vertical tangency of the body and the base of the neck. Similar to the heel of a bottle, the shoulder is a transition zone between two other major portions of a bottle.

Throat - See Bore.

Return to

the Bottle Glossary page

Go to the

Homepage

SEARCHING THIS WEBSITE:

To do a word/phrase

or image search of this website

one must use the following Google search link:

Search the SHA/BLM Historic Glass Bottle Identification & Information

Website

(Note: Search results for this website will be just below the

final top-of-the-page Google paid ads.)

1/1/2024

This website created and managed by:

Bill Lindsey

Bureau of Land Management (retired) -

Klamath Falls, Oregon

Questions? See

FAQ #21.

Copyright © 2024 Bill Lindsey. All rights reserved. Viewers are encouraged, for personal or classroom use, to download limited copies of posted material. No material may be copied for commercial purposes. Author reserves the right to update this information as appropriate.