Machine-made bottles portion

of

the Dating Key

HOME:

Bottle Dating: Machine-made bottles

Click here to move directly to the list of machine-made dating questions.

General Machine-made Diagnostic Features: Machine-made bottles will exhibit most or all of the diagnostic characteristics explained and illustrated below. (This summary is largely an amalgam of Toulouse 1969b; Miller & Sullivan 1981; Jones & Sullivan 1989; Boow 1991; Cable 1999; Miller & McNichol 2002; Miller & Morin 2004; empirical observations.) It should be noted that features #1, #3, #4, #5, and #6 are primary indicators of machine-made manufacture. Feature #2 (mold seam diameter) is not as strongly diagnostic as the primary indicators as mouth-blown bottles sometimes can have very fine mold seams. Feature #7 describes a couple glass related features that are quite consistent in machine-made bottles, but not diagnostic, i.e., mouth-blown bottles may sometimes have few/no bubbles in the glass and even thickness. (Note: the term "parison mold" and "blank mold" are synonymous for the first mold in the two mold machine process.):

1. Vertical side mold seams which usually (see the Note box below point #3 for an exception) run up to the highest point of the finish and often onto the extreme top finish surface (i.e., onto the rim or lip). On many early (very early 1900s into the 1920s) and occasional later (1930s and later) machine-made bottles the vertical body/neck and finish mold seams are discontinuous and offset from each other; click offset seams for a picture of this attribute. These vertical seams - finish mold seams vis-à-vis the upper neck mold seams - may range from just slightly offset to 90 degrees offset (like shown at the linked image above). The offset is a function of the orientation of the parison relative to the two molds (parison and blow molds) used on the particular machine, or occasionally, to the hot parison "sticking" to the neck ring of the parison/blank mold when transferring to the blow mold (Ceramic Industry 1949:14-15). There are also no horizontal tooling marks present on the finish and/or upper neck as would be observable on the finish of mouth-blown bottles.

2. The side mold seams on most machine-made

bottles tend to be finer (narrower and lower) - though sometimes

sharper and/or visually distinct

than mouth-blown bottle mold

seams although many mouth-blown bottles have

very thick and distinct seams due to less precise mold construction or

fitting. The statement about machine-made bottles may seem

contradictory (finer but more visually distinct) but is a function of the

higher machine blowing pressure. Earlier machine-made bottles

(1905-1920s) tend to have somewhat thicker/higher mold seams than later

machine-made bottles due to the increasing precision in mold machining and

machinery in general as time progressed. Most machine-made bottles

have mold seams about the thickness of a hair

while most visible mouth-blown mold seams tend to be several times as thick,

higher, but more rounded. (Mold seam thickness and how high it

protrudes [height] is of only moderate use in telling a machine-made bottle

from a mouth-blown bottle, though if a bottle fragment has a hair fine mold

seam, it is highly likely to be from a machine-made bottle.)

4. "Ghost" seams are usually present on the neck,

shoulder, and/or body of the bottle

if made by a

blow-and-blow machine (like the Owens Automatic Bottle Machine).

These are faint, somewhat wandering, hairline seams which if present

(usually) are sporadically visible on the sides of machine-made bottles.

The ghost seams are caused by the parison mold parts and if visible enough will be

"attached" to the vertical seams in the finish. Click on

ghost seam to view a close-up explanatory picture of this attribute.

Be aware that bottles and jars made by early to mid-20th century

press-and-blow machines do not usually have ghost seams, since the

parison mold was usually one-piece, but will

typically have a

valve mark on the base

(see #6 below). 6. The presence of a circular valve mark on the base of a bottle (typically a wide mouth bottle or jar) is sure evidence of machine-made manufacture by a press-and-blow machine. This is discussed further as Question #14 below. 7. Machine-made bottles tend to have few if any bubbles in the glass and the thickness of the glass is usually more uniform throughout the bottle as compared to mouth-blown bottles. This is especially true of later machine made bottles, i.e. from the late 1920s on. (Note: The presence or absence of bubbles in the glass and relatively even distribution of the glass throughout the characteristic is not a primary feature of either machine-made or mouth-blown bottles, though there are strong trends. (For more details about the production of machine-made bottles visit the machine-made bottles section of the Glassmaking & Glassmakers page.)

Narrow neck press-and-blow machine?

It should be noted that one fairly early

press-and-blow semi-automatic machine was designed to produce

narrow bore bottles. It was noted in 1910 that the

Cumberland Glass Company (Bridgeton, NJ) had "...succeeded in

perfecting a machine that will satisfactorily produce narrow neck

bottles, such as catsups, beer bottles, etc., at a big saving over the

hand method."

The method used was unusual and may have been

unique in bottle-making history: "The machine differs from

all others, and in getting the neck upon the bottle, the vessel is

made in two sections, the neck being put upon the bowl with a second

operation. This is accomplished so that there is no perceptible mark

upon the bottle showing the joint, and the bottle stands every

possible test as to strength. The machine is operated much as all

pressing machines are..." (National Glass Budget 1910; Lockhart pers.

comm. 2007).

Although products of this machine are not

conclusively known a bottle such as the one at this link -

offset seams shoe polish bottle - may well be a product of the

described machine as there is a distinct and abrupt interface edge at

the shoulder where the mold seams for both the body and neck end and

are offset. This little bottle has a moderately narrow neck and

a distinct

valve or ejection mark on the base indicating press-and-blow

machine manufacture. Added evidence to this theory is that an

identical shape and size (2 oz.) "Round Shoe Polish" bottle is shown

in the "Machine Made Ware" section of Cumberland's 1911 catalog

(Cumberland Glass 1911). More specifically, non-Owens machine-made bottles with narrow necks (similar to the amber beer bottle pictured earlier) will always date after 1908 (and typically after 1910) regardless of what type machine they were produced on since the first blow-and-blow semi-automatic machines capable of producing narrow necked bottles (copied after English machines invented somewhat earlier) were first made or used at that time in the U.S. (Boow 1991; Cable 1999). Very few narrow neck bottles made on the Owens machines will pre-date that time also. Bottles or jars with wide mouths (like the jar pictured under Question #15 below) may occasionally pre-date 1905, to as early as about 1893, since semi-automatic press-and-blow machines were being used to some degree by the mid-1890s. (The first production bottles known to have been made on semi-automatic machines were wide mouth Vaseline bottles made by the C. L. Flaccus Glass Co. [Beaver Falls, PA.] in 1894 [Lockhart et al. 2007d].) It is thought that probably all pre-1905 semi-automatic bottle machine production in the U.S. was relegated to wide-mouth bottles/jars due to limitations of the press-and-blow machines at that time (Toulouse 1967; Miller & Sullivan 1981; Jones & Sullivan 1989; Cable 1999; Miller & McNichol 2002; Lockhart pers. comm. 2003). The 1908 photo below is from the Lewis Hine collection (Library of Congress) and shows an early, probably O'Neill (Barrett 2011) semi-automatic press-and-blow 4 mold milk bottle (which have relatively wide mouths) machine which came with the following caption: "Machine that blows 4 milk bottles at a time. No "lung blowers" employed. Travis Glass Co., Clarksburg W. Va. Manager says machines are fast coming into play in bottle industry, plans eventually to have machines in place of "carrying in boys." Location: Clarksburg, West Virginia" (Library of Congress). This two table semi-automatic machine would have been hand fed with glass (furnace likely to the right) and does have the two different mold sets with the parison molds (where the first "press" part of the cycle took place) the set on the right. Blowing air would have been supplied by the hose visible at the top of the set of blow molds to the left, where the final "blow" part of the cycle took place.

A review of Illinois Glass Company

catalogs from the early 1900s shows that wide mouth bottles apparently made

by semi-automatic "Machine Made" methods first appear in the 1906 catalog

and were not present (or at least specifically noted) in catalogs before that time.

As the

Illinois Glass Company was one of the largest glassmakers of the time it is

reasonable to assume that semi-automatic machines producing wide mouth bottles/jars

became common throughout most of the glass industry about that same time. This allows for a high probability begin date of around

1900 to 1905 for most wide mouth, machine-made bottles and jars (Illinois

Glass Company 1903, 1906, 1908). However, since the products of

automatic and semi-automatic non-Owens machines date from the same era as

the Owens machine and are largely indistinguishable, they are all considered

together on this machine-made bottle dating page. Mouth-blown to Machine-made Transition Era: The transition from mouth-blown to machine-made bottles was a fairly long and circuitous road. There were numerous reasons why machines were not immediately accepted - some of which follow (taken primarily from Toulouse 1967, 1969a & 1971):

The link below allows a user to view an amazing short movie clip that shows two different early Owens Automatic Bottle Machines in operation. The first machine is the "Machine #5" which the film clip script notes as having been made in 1906 in Toledo, Ohio. This was apparently the earliest of the viable commercial machines, and in fact, the clip was made to help promote and sell the machine to potential buyers. The first person shown operating Machine #5 is Emil Bock, a mechanical genius who worked with Michael Owens from the "bicycle pump" early machine experimentation days (1890s) and transformed Mike's ideas into workable steel machines. Michael Owens is the second person shown picking up and examining a couple beer bottles. This clip is also reported to be the only movie ever made showing Michael Owens who was reputed to be "camera shy." The last half of the clip shows a much larger, 15 head "AQ" machine in operation at an Owens-Illinois plant in 1959 (Walbridge 1920; Owens-Illinois Co. 1959; Perry pers. comm. 2007). Of particular note, the 1959 portion of the clip shows the sucking up and cutting off of the glass from the continuous tank by the parison or blank mold. Towards the end it also shows the shift of the parison from the parison/blank mold to the blow mold. Film clip is compliments of the Owens-Illinois Glass Company. (Many thanks to Phil Perry - a senior engineer with that company - who graciously provided this clip.)

Film clip of an early Owens Automatic Bottle Machine in operation. |

As with mouth-blown bottles, more precise dating of a machine-made bottle can be done with some confidence by using one or more of the various diagnostic features outlined in the questions on this page. Unlike the first portions of the Dating key (Questions #1 through #3 on the main Bottle Dating page; #4 through #7 on the Mouth-blown bottles portion of the dating key), each question on this page is an independent dating tool for which the response is not predicated on the outcome of any of the other questions. Thus, these questions do not have to be viewed in order. The question numbers on this page continue where they left off on the mouth-blown bottle portion of the key.

|

Question #8: Is the bottle glass color aqua (aquamarine or very light green), essentially colorless (clear), or a color other than colorless or aqua? Question #9: Are there "bubbles" present in the glass? If so, how many and what size/shape? Question #10: Does the bottle have the following statement embossed on its side or on the base? FEDERAL LAW FORBIDS SALE OR REUSE OF THIS BOTTLE Question #11: Does the bottle base have similar markings to those on the bottle pictured? (These markings are those of the Owens-Illinois Glass Company.) Question #12: Does the bottle have a finish (lip) that was sealed with a cork, sealed with an externally threaded screw cap, or sealed with some other type closure? Question #13: Does the bottle have what appears to be a painted or enameled label, lettering, and/or decoration? Question #14: Does the bottle have a shallowly incised circle on the base that is (usually) between 1/3" to 3/4" (10-18mm) in diameter? Question #15: Does the bottle have a narrow mouth (bore/finish) or does it have a wide mouth (bore/finish)? Question #16: Does the bottle have embossed (or labeled) contents or volume capacity information? Question #17: Does all or a portion of the bottle base have a textured pattern, i.e., stippling or knurling? Question #18: Does the bottle have any type of glass/bottle makers markings embossed on the base (typically) or body (occasionally)? |

Read through each of the questions to see which have pertinence to the bottle you wish to date. Hyperlink to other web pages that are suggested in each question for added information and then read the summary statement at the end of this page which will give some suggestions on where on this website a user could or should proceed to. Keep track of the specific diagnostic feature date ranges listed in each question you consult, and once to the end of the page, use that information to ascertain the likely production date range of your bottle. See dating examples #1, #4, & #5 on the Dating Examples page for guidance.

As explained previously above, be aware that the 1905 "earliest" date used in the questions is not absolute. There were some wide mouth, semi-automatic machine produced bottles (albeit a very low percentage) which had machine-made characteristics (minus a suction scar) than can date back as early as the mid-1890s.

Lets begin with Question #8

right below...

QUESTION #8: Is the bottle glass color:

A. Aqua (aquamarine or very pale green);

B. Essentially colorless (clear); or

C. A color other than colorless or aqua?

The color of the glass in a machine-made bottle can, to a limited

degree, be useful in dating. (As with all of the dating points on this

page, color must be considered in conjunction with other diagnostic

characteristics in arriving at a probable date or date range for any given

bottle - the "preponderance of evidence" concept.) With the increasing dominance of the

automatic bottle machine in the 1910s and on, bottle shapes, sizes, and colors became more and

more standardized and uniform, i.e. much less variety. Glass making technology progressed so

that colorless (aka "clear") glass became much cheaper to produce and displaced aqua as the

dominant bottle glass color for containers where being able to see the products

natural color was an important consideration. An assortment of other colors were

still common - particularly

amber

and to some degree,

cobalt blue - but the range of common colors present in

machine-made bottles was restricted compared to bottles produced in the

19th century. See the

Bottle/Glass Colors page for more information on this fascinating

subject.

A. Bottle made of aqua glass - A machine-made bottle made of aqua glass - which is not a soda bottle or canning jar - is most likely to date from or prior to the 1920s.

Click

on

Groves Chill Tonic

to view a picture of an aqua medicinal from the 1910-1920 era. (The

bottle pictured in Question #9 below with a plethora of bubbles in the glass

would be considered a particular deep shade of aqua.) The amount of

aqua glass bottles produced declines throughout this period so that by the

mid to late 1920s the dominant colors for machine-made bottles (excluding

soda bottles and canning jars) is colorless or amber. Aqua

pretty much disappears by the early 1930s as a bottle color with the

notable exception of soda bottles (and many canning jars) which continued to be produced in various

shades of aqua up until recent years (Miller & McNichol 2002,2010; empirical

observations). Royal Crown Cola, Dr. Pepper

(both a

greenish aqua), and

Coca-Cola ("Georgia Green") are familiar examples of late

era aqua bottles

(Toulouse 1971).

For more information on this color, click aqua to go to

its description on the Bottle Colors page.

B. Bottle is of largely colorless

(aka "clear") glass

Machine-made

bottles with colorless glass can date from any time after 1905, though there

is a relatively reliable dating break possible based on the type of

colorless glass. In the production of colorless glass numerous methods

- mechanical, physical, and/or chemical - were used to decolorize glass

(Tooley 1953). Decolorizing is in essence neutralizing the effects of

the iron and carbonaceous impurities in the glass mix in order to obtain as

colorless of glass as possible. The primary physical (masking) agents used in the

first half of the 20th century were manganese dioxide, selenium, and

arsenic. All potentially leave a very slight residual color to the glass that is

usually visible when looking closely at the thickest

portion of the base or sides. For more information click

colorless glass

to go to that section of the Bottle Colors page.

Manganese dioxide causes the glass to have a very slight lavender or amethyst tint which is amplified to varying degrees with exposure to sunlight (or artificial radiation). Manganese oxide was found to be difficult to work with - particularly in the open glass furnaces used for the Owens Automatic Bottle Machine - and was eventually overshadowed by selenium and arsenic for decolorizing (Miller & Pacey 1985). When selenium or arsenic (or a combination of the two) is used to decolorize glass, it often leaves a very faint "straw" cast to the thick glass portions which is not affected or intensified by sunlight. (Note: It has been thought for many years that selenium produced the "straw" cast to otherwise colorless - and almost exclusively - machine-made bottles. However, it is now thought to be a function of using arsenic - probably in tandem with selenium - as the decolorizer [Tooley 1953; Lockhart pers. comm. 2003].) The following dating refinements are possible with colorless machine-made bottles:

1. The large majority of machine-made bottles with a slight to moderate lavender or amethyst tint - indicating manganese oxide was used as the decolorizer - date between 1905 and the early 1920s (top picture above right; click small amethyst wide-mouth bottle for a picture of this entire bottle) though some can date as late as the 1930s. Machine-made soda bottles were generally not decolorized with manganese after 1914 (Lockhart 2006a).

2. The large majority of machine-made bottles with a pale "straw" color tint (bottom picture above right) - indicating selenium and/or arsenic use as a decolorizer - will date no earlier than 1912 (Lockhart 2006a & b). Based on empirical observations, one or both of these decolorizers are still in use today although after the 1960s other decolorizing agents and glass producing processes were used resulting in less abundant "straw" tinted bottles.

C. Bottle made of some other color of

glass

If the bottle has

some other glass color no useful general dating information is possible. However,

some bottle-type specific dating refinement is possible based on specific glass

colors for both machine-made and mouth-blown bottles; see the

Bottle/Glass Colors and

Bottle Typing/Diagnostic Shapes pages for more information. Move to the other questions below for more dating opportunities.

QUESTION #9:

Are there "bubbles" present in the glass? If so, how

many and what size and shape?

"Bubbles" are air or gas filled cavities within the glass. The image to the left is a close-up of a bottle with bubbles in atypically high quantity for illustrative purposes. Bubbles are caused by an assortment of irregularities in the production process including a glass pot or tank that was too hot or not full enough, glass cut-off or shearing irregularities, and various gob feeder problems. In the glass making industry, small bubbles were referred to as "seeds" and larger bubbles as "blisters" (Tooley 1953). Similar to the color question above, the presence of bubbles in the glass can help some in pinning down the date of a machine bottle, but must be used in conjunction with other features to more confidently narrow down a date range as it is not conclusive by itself.

Some authors - most notably Jones & Sullivan (1989) - believe that "the number and size of bubbles has absolutely no connection with the age of the glass." This appears quite true of mouth-blown bottles, though empirical evidence suggests some dating trends with regards to machine-made bottles. More specifically, there appears to have been an increase in the homogeneity and uniformity of glass as the technological advances of the machine era proceeded. However, this feature is still a tenuous one since there are many early machine-made bottles with few or no bubbles. Conversely, machine-made bottles after the 1920s which have numerous and/or large bubbles exist but are rare (Girade 1989; Lockhart pers. comm. 2003). See the Bottle Body Characteristics & Mold Seams for more information on bubbles.

As a general rule of thumb, earlier machine-made bottles and jars (i.e., 1905 to 1910 [mid-1890s for wide mouth ware] through the 1920s) will have more and larger bubbles than later machine-made bottles (early 1930s and later) when bubbles in the glass became a much rarer occurrence due to ever more refined glassmaking technology. Larger bubbles (~1/8" and larger) and/or numerous bubbles of all sizes are more prevalent in bottles manufactured during the early machine period - 1890s (wide mouth ware) to early 1920s. The absence of bubbles or presence of only a very few small "seed" bubbles (less than a pin-head in size) or very narrow "V" shaped bubbles, denotes a bottle that is more likely to date from or after the 1930s. (The "V" shaped bubbles are discussed on the Bottle Body Characteristics & Mold Seams page.)

If one takes a look at glass bottles found in supermarkets today they would be hard pressed to find even one bubble in all the bottles looked at combined as technology has all but eradicated this flaw in glassmaking.

QUESTION #10:

Does the bottle have the following statement embossed on its side or

on the base?

FEDERAL LAW FORBIDS SALE OR REUSE OF THIS BOTTLE

In the U.S., National Prohibition was repealed in late 1933 and was subsequently followed by the passage of Federal laws prohibiting the reuse or sale of used liquor bottles. This requirement was intended to discourage the re-use of bottles by bootleggers and moonshiners, though the biggest discouragement to that illicit activity was that liquor was now legally available. On January 1st, 1935 all liquor sold in the United States was required to be in bottles that had the above statement embossed in the glass (Busch 1987). The statement was not required on wine or beer bottles, the latter category which was - and to some degree still is - bottled in re-useable bottles.

If your bottle has this statement embossed in the glass, it is a machine-made liquor bottle that dates between 1935 and the mid-1960s. This inscription is found only on machine-made bottles, with the rare exception of some Mexican-made (for the U. S. market) bottle being mouth-blown during that era.

In 1964, the law requiring this statement was repealed. Be aware however that for some years after 1964, liquor could still be found in bottles with this phrase since not all liquor producers switched immediately to new bottles due to the expense of new molds or to deplete an existing supply of bottles (Ferraro 1966) Click 1974 liquor bottle to view a picture of the base of a liquor bottle which has the reuse prohibition embossing though was made well after (10 years) the regulations requiring the statement were eliminated. The linked bottle was made by the Thatcher Glass Manufacturing Company (Elmira, NY.) and has a date code for 1974. The company used the stylized "TMC" mark from 1949 to 1985 (Toulouse 1971; Giarde 1989; Whitten 2005).

If your machine-made bottle does not have this phrase embossed in the glass it is probably either not a spirits or liquor bottle, made outside the era the statement was required, or the bottle was originally sold outside the U.S. If you know the bottle is a U. S. made/sold spirits bottle (i.e. distinctly a spirits bottle in shape or design or it has other conclusive features like brand embossing or labeling) it could date prior to 1935, though is more likely to be a post-1964 product. A pre-1935 date is possible since some spirits - particularly whiskey and brandy - were available to a limited degree by prescription through pharmacists to be used "for medicinal purposes only." Most pre-Prohibition (pre-1920) liquor/spirits bottles exhibit mouth-blown manufacturing characteristics, i.e., they are uncommonly machine-made. This is because Prohibition occurred individually in most states between 1912 and 1918, with National Prohibition finally passed in 1919 and effective in early 1920. This time span was the peak changeover from hand to automated bottle production methods. Visit the liquor bottle section of the Bottle Typing/Diagnostic Shapes page for more information on spirits bottles.

NOTE: Some references and many people believe that there are liquor bottles embossed with FEDERAL LAW PROHIBITS SALE OR RE-USE OF THIS BOTTLE, i.e., PROHIBITS instead of the word FORBIDS (Ferraro 1966). No PROHIBITS bottles have ever been observed by the author or other consultants to this website and it is believed to be a myth, though the author would welcome conclusive proof (an image) that PROHIBITS was indeed used in this context.

|

Note about a potential related

dating refinement. This can often lead to enhanced dating refinement of mid-20th century liquor bottle depending on the current information available for the glass maker. See this websites makers marking page at this link - Glass Making & Glass Makers: Bottle & Glass Makers Markings - for articles on scores of glass companies. |

QUESTION #11:

Does the bottle base have similar markings to those on the

bottle pictured below?

|

|

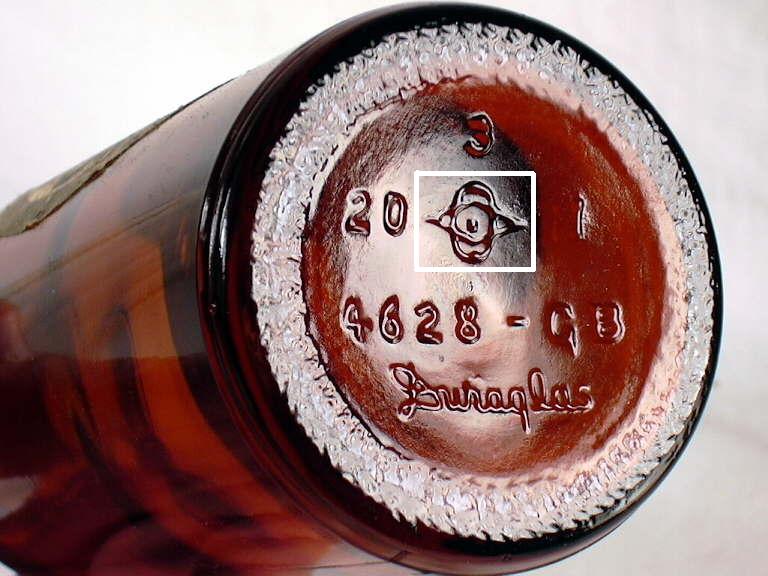

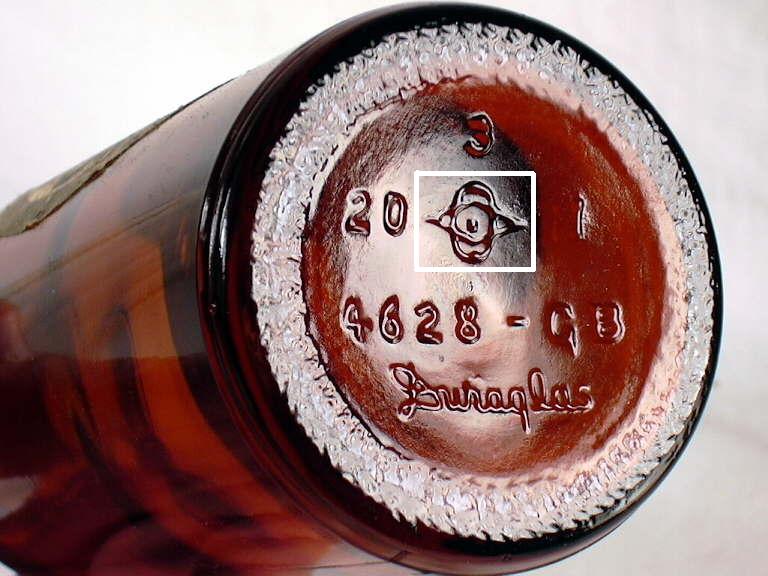

Bottles with the highlighted mark in the image date between 1930 and the mid-1950s (with some limited use of this mark until at least 1959).

The "Diamond O-I" makers mark of the Owens-Illinois Glass Co. is shown in the picture within the white box (click to enlarge). This mark is also called the "Saturn" mark by some due to its stylized resemblance. (Note: The "O" in the Diamond O-I marking is actually a vertically elongated oval, although referred to here as an "O" for simplicity.) This makers mark is very common on bottles made during the 1929-1930 to mid-1950s period as the company was (and still is) a dominant force in the bottle production world at that time (Toulouse 1971; Lockhart 2004d).

The various Owens-Illinois markings provide an opportunity to also identify which plant made the bottle and in what year. Specifically for the pictured export beer bottle, the script Duraglas marking and the stippling (molded "roughness") around the outside edge of the base were both used first in 1940, so this bottle can date no earlier than that. The "1" to the right of Diamond O-I mark is the year code and in this case obviously can not be earlier than 1941 (i.e., not 1931) because of the Duraglas embossing and stippling. In the early 1940s, realizing that single digit date codes were repeating (e.g., "0" could be 1930 or 1940), caused the company to add a period after the single digit on some bottle types - primarily soda bottles (not beer bottles) - from about that time to the mid-1940s. At that point two digit year codes (e.g., "46" for 1946) were used on most bottles types; in particular, beer, soda and milk bottles. Unfortunately, the use of the one and two digit date codes was inconsistently used by different plants and mold makers so this is not a certain rule for dating.

For example, the illustrated bottle was highly likely to have been made in 1941 since one made in 1951 would likely have a date code of "51." The "20" to the left of the Diamond O-I mark is the code for the Oakland, CA. plant* which began operations in 1936 and is still in operation today - so knowing the factory is of no use in pinning down the manufacturing date. Similarly, the bottle is paper labeled as having been used by the Columbia Brewing Inc. (Tacoma, WA.) who did business under that name from 1934 to 1953 when it became the Heidelberg Brewing Co. (Van Wieren 1995). Once again though, this bit of information does not help pin down the date. The clincher for the 1941 date is the heavier (thicker) glass that this particular bottle was made with identifying it as having been made just prior to the wartime reduction in the amount of glass used for many bottle types as a conservation effort during WWII. This bottle is also an example of how even with the relatively ample amount of information Owens-Illinois bottle bases provide, one may still need to rely on more than one piece of data (e.g., plant codes, brewery dates of operation/business) to ensure a reliable manufacturing date determination (Toulouse 1971; Lockhart 2004d; Phil Perry, O-I engineer pers. comm. 2007; Lockhart pers. comm. 2007,2011). (More on this bottle is found on the Beer & Ale Bottles Typology page.)

Between

1954 and about 1959 the Owens-Illinois Glass Co. changed the Diamond O-I marking

to a simpler "I in an O" mark (same basic mark minus the elongated diamond)

although the time of this change varied through the noted period depending

on the specific plant, mold life, and possibly bottle type. The base

image to the right is of this newer mark on a bottle made at plant #21

(Portland, OR.) in 1960 - the first year of operation for the Portland plant

(Toulouse 1971; Girade 1989; Lockhart 2004d)*. Date codes with this

later mark (still in use today) are variable with both single and double

digit codes (like in the image) observed, though recently made beer bottles

(1990s and later) seem to consistently have two digit codes (empirical

observations).

Between

1954 and about 1959 the Owens-Illinois Glass Co. changed the Diamond O-I marking

to a simpler "I in an O" mark (same basic mark minus the elongated diamond)

although the time of this change varied through the noted period depending

on the specific plant, mold life, and possibly bottle type. The base

image to the right is of this newer mark on a bottle made at plant #21

(Portland, OR.) in 1960 - the first year of operation for the Portland plant

(Toulouse 1971; Girade 1989; Lockhart 2004d)*. Date codes with this

later mark (still in use today) are variable with both single and double

digit codes (like in the image) observed, though recently made beer bottles

(1990s and later) seem to consistently have two digit codes (empirical

observations).

For a discussion of the Duraglas marking - shown on the amber beer bottle base above - see Question #17 below. Also consult the two part article by Bill Lockhart and Russ Hoenig (retired senior engineer for the Owens-Illinois Glass Co.) - located at the links below - for more information on the history and marks of the Owens-Illinois Glass Company. That company's marks are probably the most commonly encountered U. S. makers marks on bottles made in the 20th century (Lockhart & Hoenig 2018t & 2018u).

Owens-Illinois Glass Company Part 1 - History.

Owens-Illinois Glass Company Part 2 - Logos & Codes.

When present, bottle makers marks can be an excellent tool for helping with the dating of historic bottles. Since there were so many different makers markings on both mouth-blown and machine-made bottles, they are not covered in this key. Makers marks are discussed more on the Bottle & Glass Maker's Markings page.

|

The top illustration shows a cork finish (i.e. cork accepting) on a prescription druggist bottle. The bottom illustration shows the same type bottle with a screw thread finish with the metal cap on. Illustrations from a 1928 Owens Bottle Company "Want Book and Catalog of Owens Bottles...for Druggists". This catalog shows the availability of both closure types from the same manufacturer in the late 1920s with the note that the screw caps are "...growing more popular every day." The company (now named Owens-Illinois Glass Co.) still offered cork finishes on prescription bottles at least until 1935, though much diminished in importance in their catalogs. |

QUESTION #12:

Does the bottle have a finish (lip) that was:

A. Sealed with

a cork;

B. Sealed with an externally threaded screw cap; or

C. Sealed with some other type closure?

The cork finish versus screw-thread finish can be helpful in dating machine-made bottles but only allows for a moderately accurate dating break which to a large degree is bottle type specific. Cork is still commonly used for sealing bottles containing wine and champagne, occasional liquor/spirits bottles, and rarely some specialty food product bottles.

The utility here for dating is that certain types of bottles made the transition from cork accepting to screw-thread finishes during the mid-1920s through the 1930s; see 1928 illustrations to the right. The bottle types that made the switch during this era are the majority of medicinals, food, and ink bottles; most liquor/spirits bottles; and some non-alcoholic, non-carbonated beverage bottles. (If the type bottle you have is in doubt as to its likely use, visit the Bottle Typing/Diagnostic Shapes page for identification information.)

|

|

External screw-threads were first used during the mid-19th century though almost exclusively on canning jars including the famous Mason's "1858" jar. By the 1890s and early 1900s external screw-threads were being used occasionally on mouth-blown liquor/spirits bottles & flasks, some commercial food bottles, ink bottles, and other bottle types more rarely. The use of screw threads was still limited by the lack of precision in hand production processes. These older external screw thread bottles would likely have keyed out as mouth-blown in Question #2 because of the ground lip surface present on most mouth-blown external screw-thread bottles.

External screw threads became more common as fully automatic bottle machines dominated over hand production methods, since machines produced much more uniform and precise finish dimensions allowing for standardized caps. External screw-threads came to dominate closure types by the Depression (1930s), except on soda and beer bottles. For more information go to the Types of Bottle Closures page and/or the Types of Bottle Finishes page, both of which provide much more information on this complex subject including the distinctly different types of screw threads.

A. Cork style finish - The bottle you have has a finish that accepted a cork as the closure and is not a soda, beer, wine/champagne, or liquor bottle. Cork closure, machine-made medicinals, food, inks, and some non-alcoholic beverage bottles usually date prior to the early 1930s, though there are numerous exceptions.

|

Plastic caps for screw thread finishes can be an excellent tool for dating. Bakelite - an early thermosetting plastic - made its debut in 1927 as a screw cap closure material though was first patented in 1907 (Berge 1980). This provides a terminus post quem (earliest date of use) of 1927 for bottles with the plastic cap still present. The bottle illustrated is from a 1932 Owens-Illinois Glass Co. (Toledo, OH.) druggist bottle catalog and clearly shows what they call a "molded cap" on a "prescription ware" bottle. |

B. External ("screw") thread finish - The bottle you have has external screw threads - which are usually either continuous or non-continuous or variations on these themes. Most all types of machine-made bottles with external screw threads date from the late 1920s or after, though some types - like catsup bottles - were commonly screw-threaded from the beginning of machine manufacture in the early 1910s.

C. Other closure/finish type - There are a lot of finish styles that accepted crown caps, lightening stoppers, or other types of closures which do not resemble either of the choices here. If your bottle does not fit "A" or "B" above, you will need to visit other site pages like Bottle Finishes & Closures and/or Bottle Typing/Diagnostic Shapes for more information.

QUESTION #13: Does the bottle have what appears to be a painted or enameled label, lettering, and/or decoration?

|

|

Applied color labeling or lettering (also known as ACL or pyroglazing) was a common way of permanently labeling or owner marking a bottle without the use of fragile paper labels. It was most common by far on soda and milk bottles, but can occasionally be found on other types of bottles. The ACL process is explained on the Bottle Body Characteristics & Mold Seams page. See the image to the right for an example of a simple two "color" (black and white) ACL soda bottle.

An ACL soda or milk bottle typically dates no earlier than 1933 (possibly 1931 when Owens-Illinois Glass Co. was experimenting with the process [Hoenig pers. comm. 2/2019]) when the ACL process was first adopted for commercial use in the United States (Girade 1989), with almost complete acceptance by bottle makers (and users) by the early 1940s (Lockhart pers. comm. 2003). Many beverage and some other types of bottles are still produced today with ACL's (e.g., Corona™ Beer) providing no termination date for this feature.

The following recent article - available only on this website - is highly recommended for those wanting to know just about everything about ACL's:

Lockhart, Bill and Bob Brown (with contributions by Chris Weide and Russ Hoenig). 2019. The Glamorous Applied Color Labels. Historic Glass Bottle Identification & Information Website, E-published September 2019. A comprehensive article on the history, processes and use of ACL labeling beginning in the early 1930s. This article is available on this site at: http://www.sha.org/bottle/pdffiles/ACLArticle2019.pdf

Also see the following article on the first soda bottle to sport the new ACL labeling:

Brown, Bob and Bill Lockhart. 2024. Jumbo - A Super Cola. America's First Applied Color Label Soda Bottle. Historic Glass Bottle Identification & Information Website, E-published April 2024. As the title notes, this article is on the first documented soda bottle utilizing the Applied Color Label process for product information instead of a paper label and/or embossing. This article is available on this website at the following URL: http://www.sha.org/bottle/pdffiles/JumboFirstACL.pdf

(Note: It should be pointed out that embossed milk and

soda bottles continued to be made well after similar ACL versions were

dominating the market, with embossed milk bottles made into the 1950s and soda

bottles into the 1960s and later [empirical observations]).

QUESTION #14: Does the bottle have a shallowly incised circle on the base that is (usually) between 1/3" to 3/4" (10-18mm) in diameter?

A valve or ejection mark on the base of a bottle is a definitive indication of machine-made manufacture by a press-and-blow type machine (Miller & Morin 2004). This mark was formed by machines that utilized a push-rod valve to eject the partially expanded parison out of the one-piece blank mold (the "press" part of the process) to be grasped by "transfer tongs" when shifting the parison to the second blow mold (the "blow" part of the machine process) (Tooley 1953). To view illustrations of how press-and-blow machines operated and how the valve/ejection mark was formed, click on the following links which are of the Lynch Milk Bottle machine cycle: press-and-blow machine cycle - stages 1-3; press-and-blow machine cycle - stages 4-7.

A valve mark is usually perfectly round and roughly 1/2" inch (12-14 mm) in diameter though can occasionally be a bit smaller (10-12 mm) or larger (up to at least 24 mm). The circle is incised or sharply indented into the surface of the glass and can be distinctly felt by running ones fingernail over the mark. On somewhat rare occasions (by a few different glass companies) the valve rod had a mold number incised in it which would emboss the base of the bottle with this number when ejecting the parison; these numbers will always be centered in within the ejection mark (Lockhart pers. comm. 2007; empirical observations).

Valve marks are almost exclusively found on

wide mouth machine-made hollow ware - food bottles & jars, milk bottles, and canning/fruit jars.

These are all types of bottles generally made by press-and-blow machines. Toulouse (1969b) noted

that this mark is "...most often found on wide mouth foods of the 1930s and

1940s and even later, and on many milk containers." The mark is

indeed most commonly observed on wide mouth milk bottles and food jars made between

the early 1900s

through the 1940s, and occasionally after that. It is also very common on canning jars, including many that were

produced by semi-automatic press-and-blow machines possibly as early as 1898 (Birmingham 1980; Leybourne

2001). The milk bottle pictured above is covered on the

Bottle Dating Examples page. The square milk bottle base pictured

dates from the mid to late 1920s and is discussed at this link:

Blake-Hart patent milk bottle.

Valve marks are almost exclusively found on

wide mouth machine-made hollow ware - food bottles & jars, milk bottles, and canning/fruit jars.

These are all types of bottles generally made by press-and-blow machines. Toulouse (1969b) noted

that this mark is "...most often found on wide mouth foods of the 1930s and

1940s and even later, and on many milk containers." The mark is

indeed most commonly observed on wide mouth milk bottles and food jars made between

the early 1900s

through the 1940s, and occasionally after that. It is also very common on canning jars, including many that were

produced by semi-automatic press-and-blow machines possibly as early as 1898 (Birmingham 1980; Leybourne

2001). The milk bottle pictured above is covered on the

Bottle Dating Examples page. The square milk bottle base pictured

dates from the mid to late 1920s and is discussed at this link:

Blake-Hart patent milk bottle.

Valve marks are very unusual on narrow necked/mouth (bore)

bottle types though there are some exceptions as valve marks are occasionally

seen on early (1910s) machine-made beer and soda bottles. At least one manufacturer (Cumberland

Glass Manufacturing Company, Bridgeton, NJ) invented and used a type of

semi-automatic press-and-blow machine in 1910 which did produce narrow neck

bottles that most likely resulted in a valve mark on the base of the

bottles produced in the early 1910s (Lockhart pers. comm. 2006;

Peters pers. comm. 2007). Thus, the presence of a valve mark on a soda or beer bottles

would indicate a narrow manufacture date in the early 1910s.

QUESTION #15: Does the bottle have a narrow mouth (bore/finish) or does it have a wide mouth (bore/finish)?

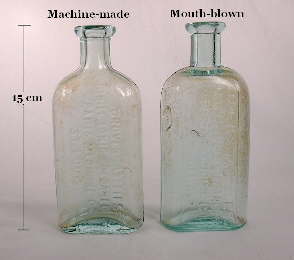

During

the mid-1890s, semi-automatic machines began to be used for the

production of bottles and jars. The first production bottles known to have

been made on semi-automatic machines were wide mouth Vaseline bottles

made by the C. L. Flaccus Glass Co. in 1894 (Lockhart et al. 2007d,

Lockhart 2015). (*See linked article below [Lockhart 2015] for more

information on the early machines that made Vaseline bottles.) For the first decade or so of use (i.e. up

to about 1905)

semi-automatic machines were useful almost exclusively for the production of wide mouth

bottles and jars (picture to the left) due to the limitations of the

press-and-blow machines in use at that time. Because of this, non-Owens machine-made

bottles (see "General Machine-made Diagnostic Features" point #5 at the

beginning of this page) with narrow necks- like the medicinal bottles pictured

below right - will

essentially always date after 1905 and virtually always after 1910. This also

largely holds true for narrow-mouth bottles made by the Owens machines which did

not really begin to dominate bottle production until about 1908-1910 (Toulouse 1967; Miller & Sullivan 1981; Jones &

Sullivan 1989; Boow 1991; Miller & McNichol 2002; Lockhart pers. comm. 2003).

During

the mid-1890s, semi-automatic machines began to be used for the

production of bottles and jars. The first production bottles known to have

been made on semi-automatic machines were wide mouth Vaseline bottles

made by the C. L. Flaccus Glass Co. in 1894 (Lockhart et al. 2007d,

Lockhart 2015). (*See linked article below [Lockhart 2015] for more

information on the early machines that made Vaseline bottles.) For the first decade or so of use (i.e. up

to about 1905)

semi-automatic machines were useful almost exclusively for the production of wide mouth

bottles and jars (picture to the left) due to the limitations of the

press-and-blow machines in use at that time. Because of this, non-Owens machine-made

bottles (see "General Machine-made Diagnostic Features" point #5 at the

beginning of this page) with narrow necks- like the medicinal bottles pictured

below right - will

essentially always date after 1905 and virtually always after 1910. This also

largely holds true for narrow-mouth bottles made by the Owens machines which did

not really begin to dominate bottle production until about 1908-1910 (Toulouse 1967; Miller & Sullivan 1981; Jones &

Sullivan 1989; Boow 1991; Miller & McNichol 2002; Lockhart pers. comm. 2003).

A review of Illinois Glass Company

catalogs from the early 1900s shows that wide mouth bottles -

certainly made by semi-automatic "Machine Made" methods - first appear in the 1906 catalog and were not

present in catalogs before that time. Since the Illinois Glass Company

was one of the largest bottle producers of the time it is reasonable to assume that

the semi-automatic machines producing wide mouth bottles/jars became

common throughout most of the glass industry about that same time. This

allows for a high probability begin date of around 1900 to 1905 for most

wide mouth, machine-made bottles and jars (Illinois Glass Company 1903,

1906, 1908). Click on the following links to see all of the pages from the 1906

Illinois Glass Company catalog that show their machine-made items:

pages 278-279;

pages 280-281;

pages 282-283;

pages 284-285;

pages 286-287. The types of bottles illustrated on these pages

would be considered typical of the earliest machine-made bottles in the U.

S., i.e., from the late 1890s to around 1910. Most other types of

bottles still would have been mouth-blown during this same era. To

summarize:

Click on the following links to see all of the pages from the 1906

Illinois Glass Company catalog that show their machine-made items:

pages 278-279;

pages 280-281;

pages 282-283;

pages 284-285;

pages 286-287. The types of bottles illustrated on these pages

would be considered typical of the earliest machine-made bottles in the U.

S., i.e., from the late 1890s to around 1910. Most other types of

bottles still would have been mouth-blown during this same era. To

summarize:

Wide mouth (bore) bottles and jars with machine-made characteristics can date from as early as the mid-1890s, but primarily date after about 1900. These bottles/jars are primarily food bottles and canning/fruit jars. A wide-mouth machine-made canning jar is pictured above left.

Narrow mouth machine-made bottles - regardless of the type machine they were produced on ( e.g., blow-and-blow semi-automatic machines, Owens Automatic Bottle Machine) - will essentially always date after 1905 with very few dating earlier than 1910. The picture to the right shows a narrow mouth machine-made bottle (left bottle) that was produced by the Owens machine and likely dates between 1915 and the early 1920s.

See the Machine-made bottle section of the Glassmaking & Glassmakers page for more information on machine-made manufacturing via press-and-blow (and other) machines.

| Lockhart, Bill. 2015. A Tour Through Time in Vaseline Jars. Historic Glass Bottle Identification & Information Website, E-published August 2015. Another exclusive article published here only; this one on the fascinating history and bottles of yet another well know product (Vaseline) that is still in production today. This article is available at this link: http://www.sha.org/bottle/pdffiles/Vaseline2015.pdf |

It was

very uncommon until the early 20th century for the capacity or volume of the

contents of a bottle to be noted in the embossing or on the label (or closure

sometimes). The image to the right shows a very late mouth-blown druggist

bottle (1914 to early 1920s) from Spokane, WA. that has the volume capacity ("12

oz.") embossed on the shoulder. The origin of volume designations is explained in an article by Bill Lockhart dealing with El Paso,

TX. soda bottlers published in The Artifact in 2003; part of which is

quoted below. (Note: This article was also re-published in Bottles and

Extras in 2006 (Lockhart 2006a) and available at this link:

A Tale of Two Machines and A Revolution in Soft Drink Bottling.)

It was

very uncommon until the early 20th century for the capacity or volume of the

contents of a bottle to be noted in the embossing or on the label (or closure

sometimes). The image to the right shows a very late mouth-blown druggist

bottle (1914 to early 1920s) from Spokane, WA. that has the volume capacity ("12

oz.") embossed on the shoulder. The origin of volume designations is explained in an article by Bill Lockhart dealing with El Paso,

TX. soda bottlers published in The Artifact in 2003; part of which is

quoted below. (Note: This article was also re-published in Bottles and

Extras in 2006 (Lockhart 2006a) and available at this link:

A Tale of Two Machines and A Revolution in Soft Drink Bottling.)

On March 3, 1913, Congress passed H. R. 22526, generally known as the Gould Amendment to the Pure Food and Drug Act of 1906. Although the Pure Food and Drug Act demanded a great deal of labeling information, it did not require the inclusion of volume specification. The Gould Amendment corrected that oversight when it stated that the "quantity of the contents be . . . plainly and conspicuously marked on the outside of the package in terms of weight, measure, or numerical count" but continued to explain that "reasonable variations shall be permitted." Although the law went into effect immediately, it clarified that "no penalty of fine, imprisonment, or confiscation shall be enforced for any violation of its provisions as to domestic products prepared or foreign products imported prior to eighteen months after its passage" (U. S. 1913:732). In other words, the industry actually had a grace period in required compliance until September 3, 1914.

In order to be in compliance with the Gould Amendment, soda bottlers in El Paso (along with those in the rest of the U. S.) had to include volume information on their containers by no later than September 1914. All bottles bearing volume data can therefore be dated as no earlier than 1913 and probably not until 1914. Thus far, I have found no datable, mouth-blown, El Paso soda bottles containing volume information. However, a few machine-made bottles from both the Magnolia Coca-Cola Bottling Co. and the Empire Bottling Works, El Paso’s two largest bottlers at that time, contain no volume information. This suggests that they were produced prior to the Gould Amendment or at least no later than 1914. All other machine-made bottles that I have examined, filled by El Paso bottlers, bore volume information. (Lockhart 2003, 2006)

Given this information, it appears that the majority of machine-made (and some mouth-blown items like pictured above) beverage, food, and medicinal bottles with embossed (or labeled) specific capacity or volume information likely date from 1913 or later. This information is of no use for bottles without volume embossing with no label still present or for bottles that did not hold a beverage, food, or medicinal product, all of which were regulated by the Pure Food and Drug Act of 1906.

One notable exception to the above is that many earlier machine-made liquor/spirits and milk bottles had volume notations embossed in the glass (e.g., "QUART," "FULL QUART," "ONE PINT," etc.) or on the label as early as 1900-1905, though the large majority of machine-made bottles with capacity information date from the 1913 law or after. Click "FULL PINT" embossed flask to see an example of an relatively early (1919) machine-made liquor flask that is embossed with FULL PINT on the shoulder. Volume notation on liquor bottles was apparently a marketing issue and seems to be related to the rise of mail-order liquor which is briefly discussed under the Tall, slender bodied, straight neck spirits cylinders (late 19th & 20th century) section on the Liquor & Spirits Bottles page. The use of volume notations on earlier milk bottles was likely associated with the demands for more cleanliness, reliability, and predictability of the product once home delivery began to be popular in the early 1900s (though reportedly began in 1878). See the milk bottle section of the typology pages for more information.

Question #17: Does all or a portion of the bottle base have a textured pattern, i.e., stippling or knurling?

The bases

of mid to late 20th century, machine-made bottles very commonly have a

textured effect covering all or a portion of the base - see the image to the

left. There were several practical reasons for this feature: the bottles would have

a reduced base surface contact decreasing

drag on the conveyor belts moving them within the factory and by

purchasers/users; to hide product related sediment; to hide the suction scar

(primarily on Owens Automatic Bottle Machine products); and for at least one

specific machine operational reason (Phil Perry, engineer with the Owens-Illinois Glass Co.,

pers. comm. 2010). The noted conveyor belt utility would only involve

the stippling on the resting surface of the bottle base - like that on the

1941 beer bottle

base below where the stippling pattern is just on the outside base edge where contact would

occur. A major practical reason for the stippling on the base was provided

by Steve Presley, Brewmaster Anheuser-Busch, Inc. (retired) and

currently brewing program instructor at the UC Davis, as follows:

"Stippling is also applied to minimize

the amount of contact between the very hot bottle bottom as it comes from

the forming machine and transitions onto the annealing lehr conveyor.

Without the stippling the thermal shock that would occur with full base

contact on the conveyor would create stresses that can cause the bottle to

burst, or reduce its overall tensile strength." (Pers. comm. 12/2016).

The bases

of mid to late 20th century, machine-made bottles very commonly have a

textured effect covering all or a portion of the base - see the image to the

left. There were several practical reasons for this feature: the bottles would have

a reduced base surface contact decreasing

drag on the conveyor belts moving them within the factory and by

purchasers/users; to hide product related sediment; to hide the suction scar

(primarily on Owens Automatic Bottle Machine products); and for at least one

specific machine operational reason (Phil Perry, engineer with the Owens-Illinois Glass Co.,

pers. comm. 2010). The noted conveyor belt utility would only involve

the stippling on the resting surface of the bottle base - like that on the

1941 beer bottle

base below where the stippling pattern is just on the outside base edge where contact would

occur. A major practical reason for the stippling on the base was provided

by Steve Presley, Brewmaster Anheuser-Busch, Inc. (retired) and

currently brewing program instructor at the UC Davis, as follows:

"Stippling is also applied to minimize

the amount of contact between the very hot bottle bottom as it comes from

the forming machine and transitions onto the annealing lehr conveyor.

Without the stippling the thermal shock that would occur with full base

contact on the conveyor would create stresses that can cause the bottle to

burst, or reduce its overall tensile strength." (Pers. comm. 12/2016).

Various stippling patterns were also added to bottle bases for largely esthetic reasons, such as the 1959 green soda bottle base to the left. None of the stippling - given the indented nature of the base center and lack of stippling on the resting surface - would have come in contact with the conveyor belt.

Stippling

is shown on both the bottle bases in the images and was typically produced by

hand punching the base plate of the bottle mold. Knurling was machine

impressed on the base plate. Practically speaking for the purposes of this

website, the difference

between the two is unimportant and the precise "look" of these base designs

varies quite a bit over time, with different bottle types and between bottle

makers. Click

knurled base to see such as defined by a Owens-Illinois engineer

(Phil Perry, pers. comm. 2010) on a bottle that is date coded most likely for

1959. (The above and linked photos courtesy of Carol Serr.) Other

types of base perimeter stippling resembles small crescents - (((((((( - which

is very common on modern beer bottles. Another design commonly seen on

the base perimeter of late 20th century and modern wine bottles is like this:

( )( )( )( )( ).

Stippling

is shown on both the bottle bases in the images and was typically produced by

hand punching the base plate of the bottle mold. Knurling was machine

impressed on the base plate. Practically speaking for the purposes of this

website, the difference

between the two is unimportant and the precise "look" of these base designs

varies quite a bit over time, with different bottle types and between bottle

makers. Click

knurled base to see such as defined by a Owens-Illinois engineer

(Phil Perry, pers. comm. 2010) on a bottle that is date coded most likely for

1959. (The above and linked photos courtesy of Carol Serr.) Other

types of base perimeter stippling resembles small crescents - (((((((( - which

is very common on modern beer bottles. Another design commonly seen on

the base perimeter of late 20th century and modern wine bottles is like this:

( )( )( )( )( ).

Knurling or stippling was first used on glass insulators in 1939, specifically by the Hemingray Glass Company (a subsidiary of Owens-Illinois Glass Co. by that time). This feature is called a "corrugated base" by insulator collectors (Bill Meier, pers. comm. 2014).

It is not precisely certain when this feature first was used on bottles although it likely first appeared in 1940 on bottles produced by the Owens-Illinois Glass Co. when they began using their proprietary "Duraglas" bottle making process (Toulouse 1971). Both of the pictured bottle bases note such with the script Duraglas on the base. This likely terminus post quem is supported by date codes noted by the author and others on bottles made by that company (Lockhart 2004d; empirical observations). So if one has a machine-made bottle with a stippled base one can be quite certain that it dates from 1940 or later.

|

As a side note, the Duraglas in upper and lower case script as shown in the images dates the bottle from between 1940 to possible as late as 1963. DURAGLAS in all capital block letters dates after 1963 to some point that the company dispensed with it altogether - probably in the 1970s (Toulouse 1971; empirical observations). This inscription is only seen on Owens-Illinois Glass Co. products. |

QUESTION#18: Does the bottle have any type of glass/bottle makers markings embossed on the base (typically) or body (occasionally)?

Machine-made

(and often mouth-blown) bottles will very frequently have embossing on the

base (image to the right and the most common location),

heel, and/or

body which identifies the actual manufacturer of the bottle. Be

aware that many times the embossing on a bottle base

is not a manufacturers or "makers mark" but instead is either related to the

product the bottle contained, the user of the bottle, or is for internal manufacturer related

tracking (e.g., mold or catalog designations) of little use in dating or

typology.

Machine-made

(and often mouth-blown) bottles will very frequently have embossing on the

base (image to the right and the most common location),

heel, and/or

body which identifies the actual manufacturer of the bottle. Be

aware that many times the embossing on a bottle base

is not a manufacturers or "makers mark" but instead is either related to the

product the bottle contained, the user of the bottle, or is for internal manufacturer related

tracking (e.g., mold or catalog designations) of little use in dating or

typology.

When present, however, makers marks - in hand with answers to the other questions noted prior - will often allow for a distinct narrowing of the date range in which a given bottles was likely produced. For example, the mark to the right inside the white box is the ubiquitous marking used by the Owens-Illinois Glass Company from 1929 or 1930 until the mid to late 1950s (ending time dependent on the bottle type and/or production factory). This bottle actually dates from 1941 as discussed in Question #11 above. As one can see, when present makers marks can be one of the best dating tools of all!

To assist with this endeavor please consult the Bottle & Glass Makers Markings page which contains links to scores of articles posted on this website which were largely produced by members of the Bottle Research Group (BRG). These articles deal with specific makers markings and the history of the companies behind those markings. This will be a "work-in-progress" over the coming years as scores more BRG articles (including revisions and updates of past articles) are planned to be "e-published" via this website on an array of other bottle makers.

In order to make full use of this comprehensive information, however, one has to know what mark or marks were used by what glass or bottle manufacturing company. If not known and the marking is either a clearly identifiable alphabetical letter or letters (like A. B. Co. for the American Bottle Company) or a distinct logo or symbol, a user must first determine the origin of that makers marking. This can be done by using the appropriate "Makers Markings Logo Table" to ascertain which mark/marks were used by what company.

|

Makers Markings Logo Tables

All the above articles and tables are now (early 2021) considered final although any may be revised in the future as new information is available. |

Once a makers marking is identified one can go to the Bottle & Glass Makers Markings page (link below) to (hopefully) find the glass makers article that pertains to the mark, if an article does exist for that particular maker.

Click the following link to

go directly to that listing of makers marking articles:

Bottle Makers

Articles

|

This completes the portion of the key that deals with machine-made bottles and is the end of the key for diagnostic bottle dating. Consider the answers and dating overlap information provided by the above questions together in arriving at a likely age range for your bottle. For some examples of how to use this information to refine your date range see the Dating Examples page. As with the mouth-blown bottles, there are a number of other physical attributes of bottles that can variably allow for more precise dating. These features, however, tend to be accurate at a bottle type or category specific level and/or are impossible to incorporate into a simple key. From this point a user must consult other pages for additional information on a given bottle. The titles of (and links to) all of the pages contained within this site can be viewed by clicking on Website Map. Peruse the titles to see if any may help with your quest for information. It is suggested, however, that a user first consult the Bottle Typing/Diagnostic Shapes page for bottle type identification which includes additional bottle category specific dating information. From that page the user will also be directed to other potentially useful website pages. Happy hunting! |

SEARCHING THIS WEBSITE:

To do a word/phrase

or image search of this website

one must use the following Google search link:

Search the SHA/BLM Historic Glass Bottle Identification & Information

Website

(Note: Search results for this website will be just below the

final top-of-the-page Google paid ads.)

5/6/2024

Return to the top of this page.

This website created and managed by:

Bill Lindsey

Bureau of Land Management (retired) -

Klamath Falls, Oregon

Questions? See

FAQ #21.

Copyright © 2024 Bill Lindsey. All rights reserved. Viewers are encouraged, for personal or classroom use, to download limited copies of posted material. No material may be copied for commercial purposes. Author reserves the right to update this information as appropriate.